产品中心

双向液压成型机系列

振动成型机系列

轻质加气混凝土系统

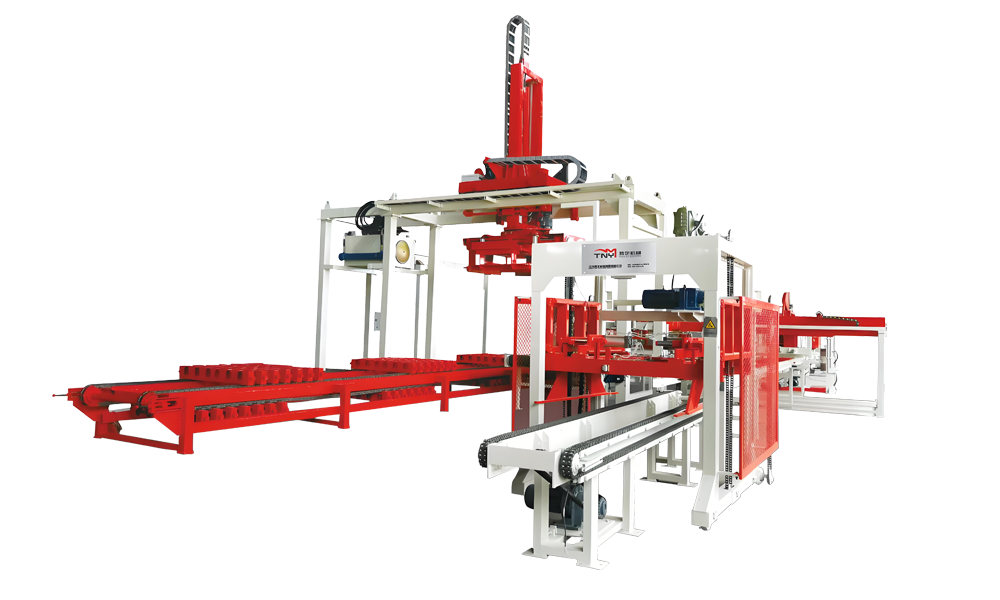

免托盘全自动码垛成套装备

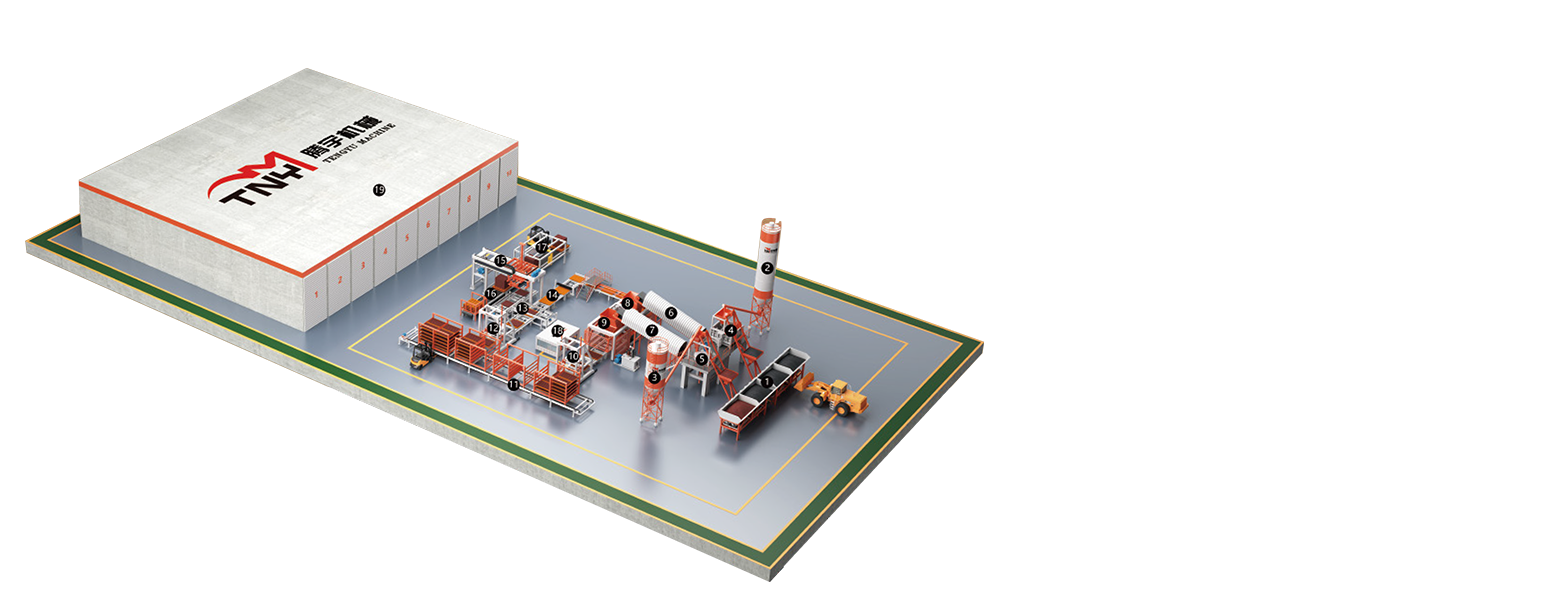

产品介绍

以细粉料为主要原料,根据不同制品来做级配;因胶凝材料可以选择水泥、生石灰、电石泥等,所以对原料的细度要求、成分要求适应范围更广,根据不同固废情况制定不同的生产工艺及配比配方。

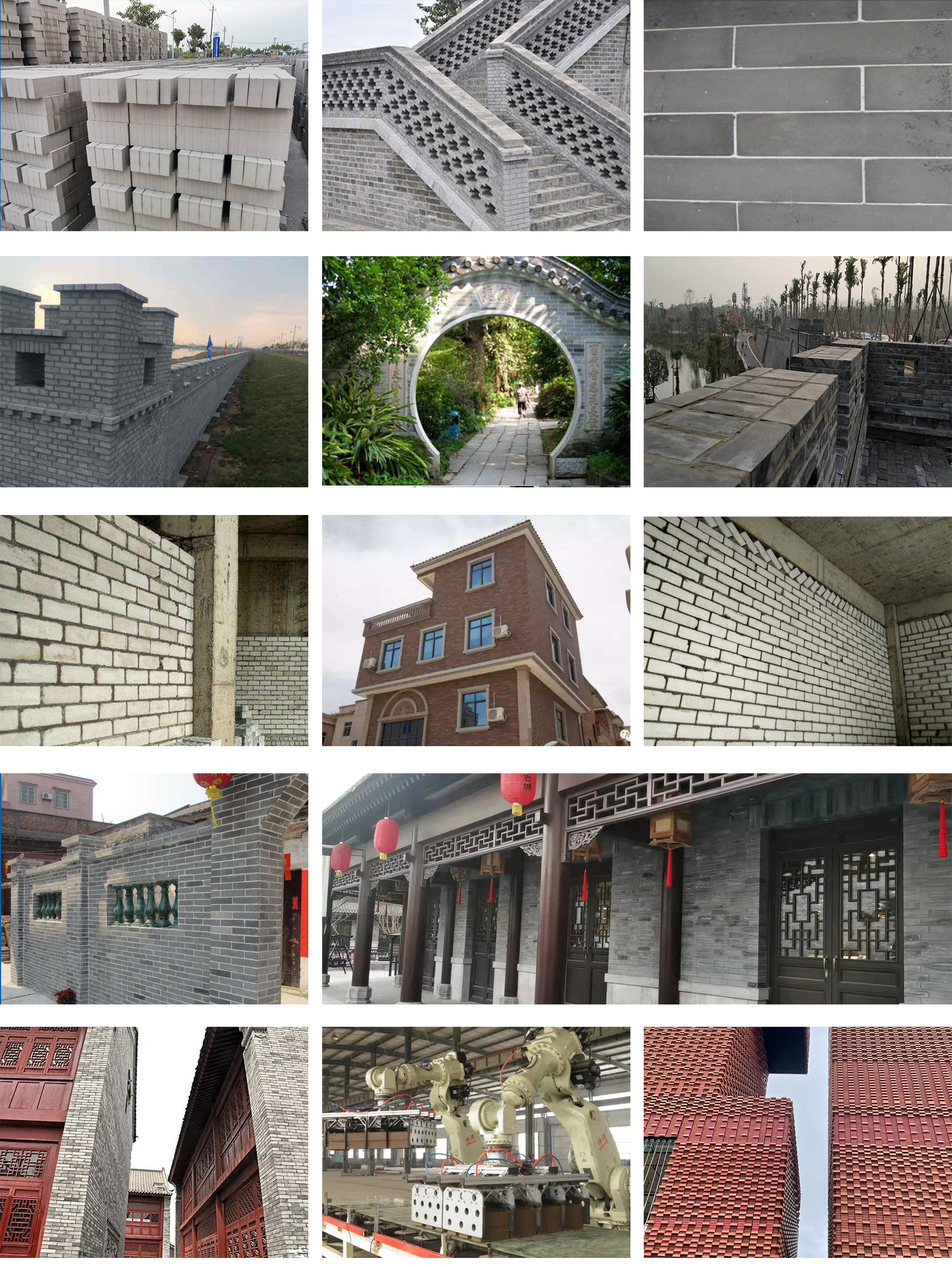

制品及市场:各种承重非承重砖,水利砖、路面砖、仿古砖等制品

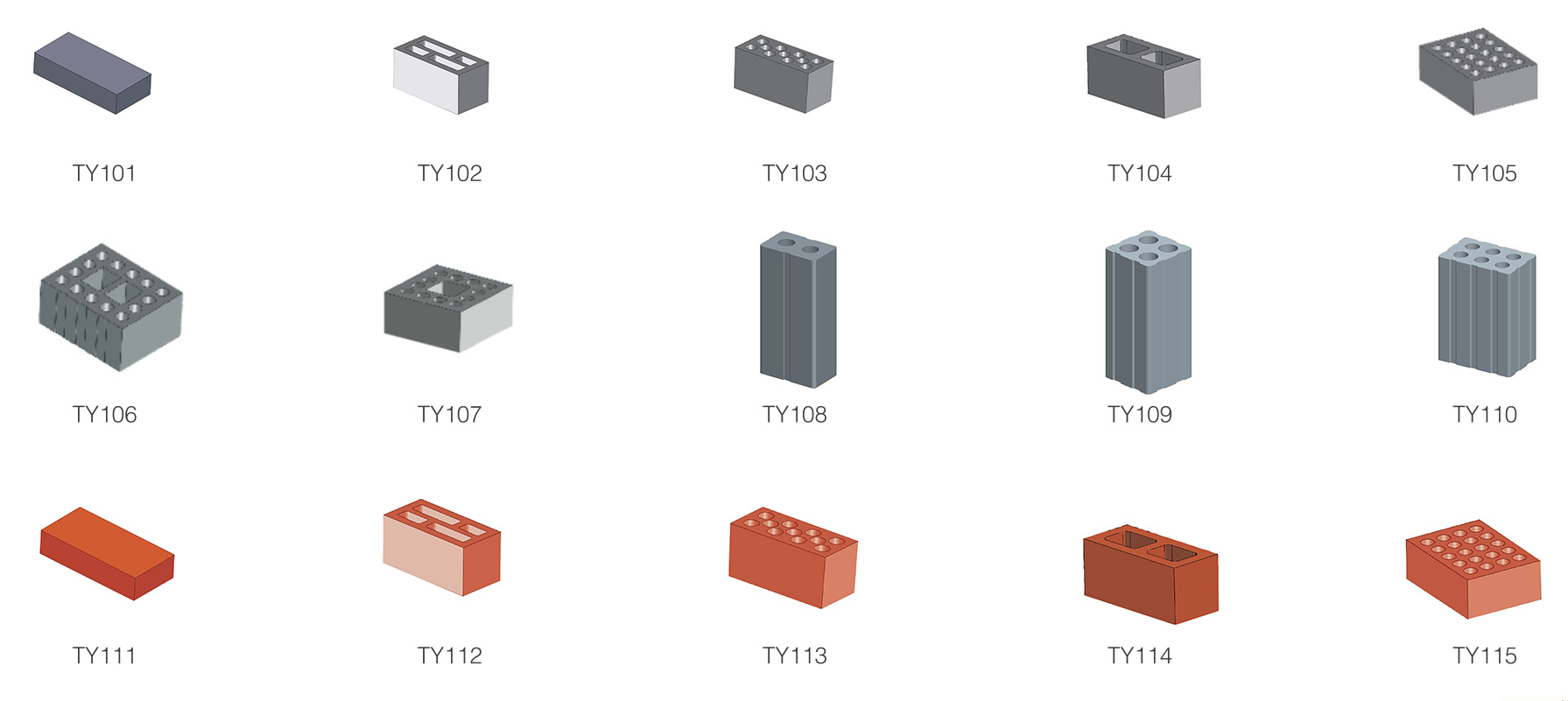

产品砖型

应用场景

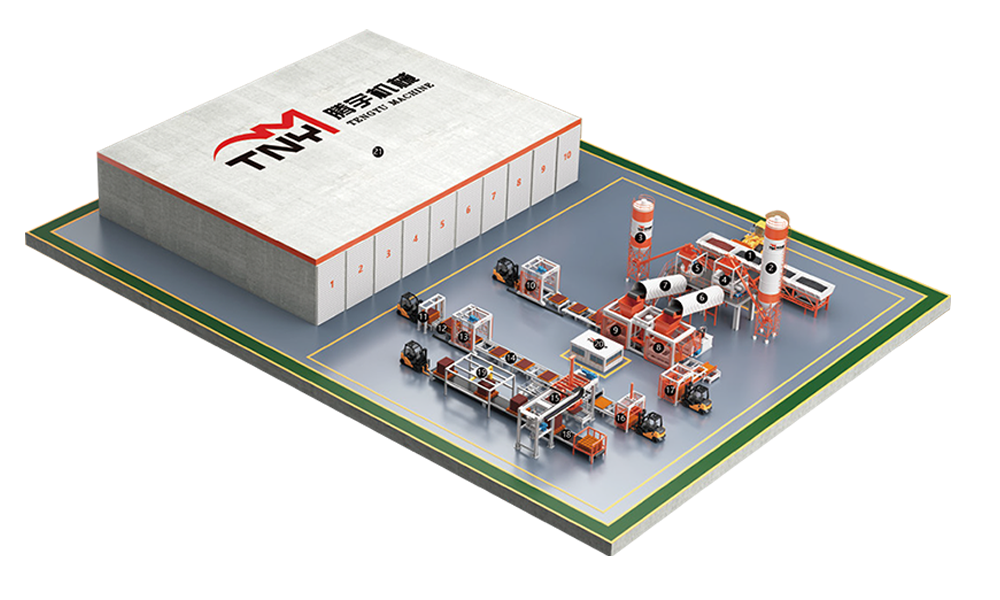

产品介绍

1、以粗骨料+细骨料结合使用,一般分为0-3mm,3-5mm,5-8mm细度等级,根据不同制品的强度等级来做相应的颗级配比;

2、制品及应用范围:各种水利护坡砖、路面砖、透水砖、仿石材砖等制品,广泛运用于市政广场、园林景观及水利、路道等项目。

产品砖型

应用场景

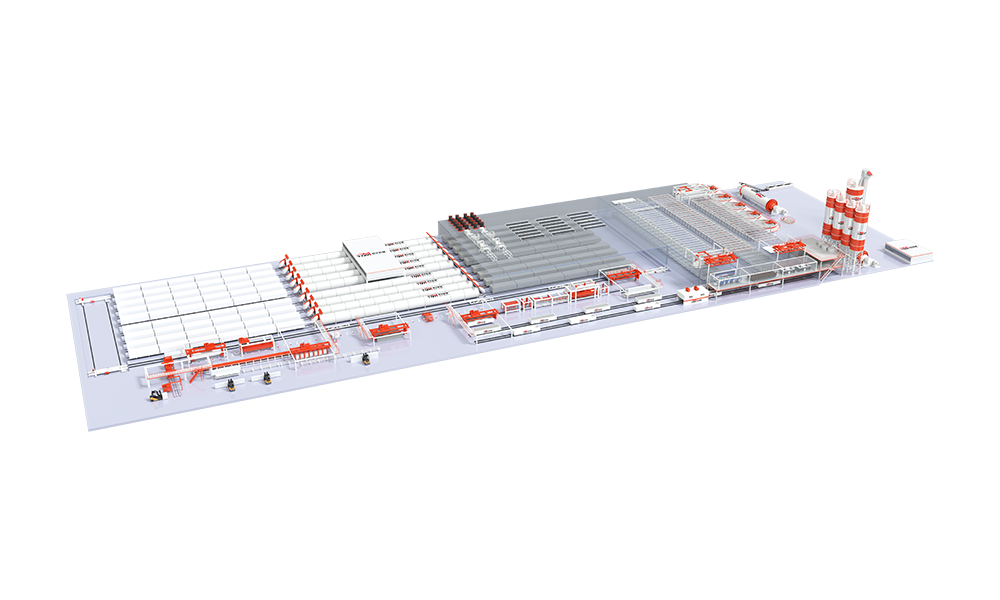

产品介绍

1、原料:富含SiO2 的尾矿是选分后的剩余物,含有大量的矿泥,且细粒尾矿细度约200目或以上。

2、制品及应用范围:加气块AAC和加气板材ALC,装配式建筑轻质隔墙板。

产品砖型

应用场景