-

-

高品质源于更专业

高品质源于更专业

主导产品有:系列加气混凝土块/板成套设备、系列固废/尾粉综合利用成套设备、系列混凝土砌块/透水砖/PC砖成套设备等。 -

-

-

2020年免烧砖机的发展前景如何

发布时间:

2020-05-21

2020年疫情几乎席卷了各行各业,除了少数几个行业影响较小外,传统制造业和外贸出口都受到了冲击。不少的小企业扛不住这次浪潮纷纷歇业。很多人都预测楼市可能会面临崩盘,但出乎意料的事房价却异常坚挺。那和楼市相关的免烧砖机行业发展前景会如何呢?

2020年疫情几乎席卷了各行各业,除了少数几个行业影响较小外,传统制造业和外贸出口都受到了冲击。不少的小企业扛不住这次浪潮纷纷歇业。很多人都预测楼市可能会面临崩盘,但出乎意料的事房价却异常坚挺。那和楼市相关的免烧砖机行业发展前景会如何呢?

如今国内的疫情已基本上控制,各个地区都放开了封锁,经济也在逐渐复苏,不少的企业家都准备大展拳脚。就目前来看不管是楼房用砖,还是地面砖、步道砖需求较之前都大大提高,投资办砖厂的人也越来越多,而免烧砖作为国家大力推广的新型墙体材料,也被越来越多的场景所需求。

另一方面疫情之后,环保问题也是越来越受到重视,免烧砖虽然不能做到完全环保(噪音污染),但相较传统烧砖自然是环保了很多。而且免烧砖机的使用原料非常广泛,就拿腾宇的免烧砖机来说,水泥、沙子、石子、陶粒、粉煤灰、炉渣、钢渣、建筑垃圾等都可以用来制砖,可以根据当地的盛产原料进行择地选择。

加之国外疫情的爆发,使得砖机的贸易出口几乎停滞,客户量损失严重,只能将目光聚焦国内用户。在供大于求的情况下,也只能通过降低利润来实现发展,几乎同各行业一样,此时砖机的优惠力度是最大的。

虽然2020年上半年制造业受疫情影响停滞不前,但随着疫情稳定,和庞大的需求环境下,免烧砖机也必将呈现出更好的发展前景。

聚焦热点

加气块/板材生产线一条完整的自动化生产线,设备主要包括原料预处理系列设备、配料浇注及搅拌控制系统、翻转吊具,JQF6切割系统、钢筋网成型及转运系统、包装系统、蒸养系统这几大部分组成。下面腾宇机械就为大家详细介绍一下这些设备,由于篇幅有限,本文主要介绍一下原料预处理系列设备。

在之前的文章中为大家介绍了加气混凝土砌块生产线的工艺流程,今天就给大家讲一讲加气板材生产线的生产工艺,希望对大家有所帮助。

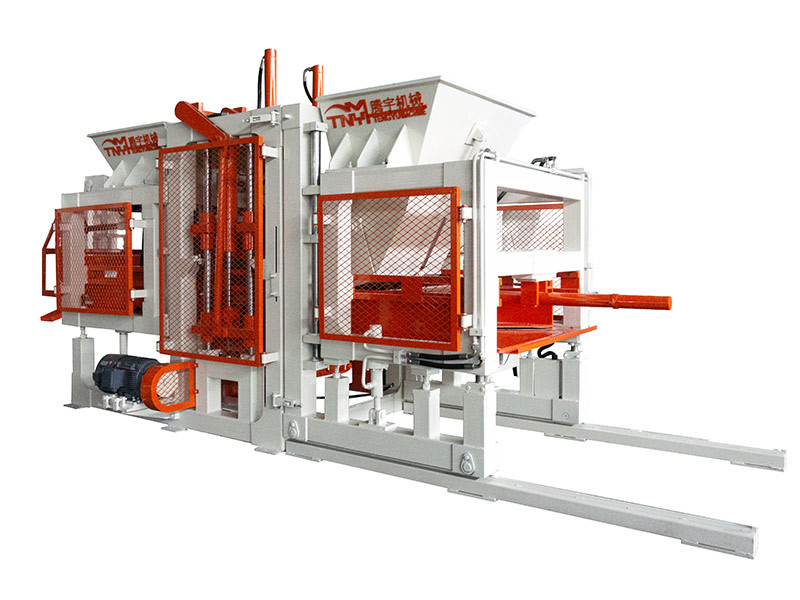

江苏腾宇机械专业生产制砖机设备及其生产线,下面就以腾宇QT12型免烧砖机为大家介绍一下全自动制砖生产线大体设备配置。

加气块因具有高强度以及优良性能一经推出就受到了建筑市场的欢迎,因此投资加气块生产线的企业也越来越多,那么在日趋成熟的2020年还有必须投资吗?投资加气生产线又有哪些优势呢,下面腾宇机械就为大家详细介绍一下投资加气块生产线项目的四大优势,帮助大家吃一计定心丸。

2020年疫情几乎席卷了各行各业,除了少数几个行业影响较小外,传统制造业和外贸出口都受到了冲击。不少的小企业扛不住这次浪潮纷纷歇业。很多人都预测楼市可能会面临崩盘,但出乎意料的事房价却异常坚挺。那和楼市相关的免烧砖机行业发展前景会如何呢?

您对我们的产品或售后服务有任何疑问吗?

只需通过以下方式联系我们:

传真:0527-8459 3038

地址:江苏省宿迁市支口街188号

微信咨询